Flanged Thermowell

A flanged thermowell is a thermowell that has a flange collar which is attached to a mating flange.

Van Stone Thermowell

Van Stone Thermowells.

Socket Weld Thermowell

A Socket-Weld Thermowell is welded into a weldalet and a weld in Thermowell is welded directly into the process thermowell.

Sanitary Thermowells

Sanitary Thermowells are designed specifically for the food, dairy, and pharmaceutical industries.

Weld-In Thermowell

Weld-In Thermowell are also known as Limited Space Thermowells. They are available in small sizes.Available Thermowell Styles

Thermowells come in 3 different styles. They are available in Stepped, Straight, and Tapered.

Thermowell Applications and Uses

Thermowells are used to provide an isolation between a temperature sensor and the environment, either liquid, gas or slurry. A thermowell allows the temperature sensor to be removed and replaced without compromising either the ambient region or the process..Thermocouple Order Code

Sheath Material

304 = 304 S.S. Most commonly used low temperature sheath material. Good corrosion resistance. Subject to damaging carbide precipitation in the 900°F to 1600°F range. (482°C to 871°C)

316 = 316 S.S. Best corrosion resistance of the austenetic stainless steel grades. Good corrosion resistance in Hydrogen Sulfide. Subject to damaging carbide precipitation in the 900°F to 1600°F range. (482°C to 871°C)

310 = 310 S.S. Mechanical and corrosion resistance similar to but better than 304 S.S. Very good heat resistance. This alloy contains 25% Cr, 20% Ni. Not as ductile as 304 S.S.

INC = Inconel 600 Best corrosion resistance of the austenetic stainless steel grades. Good corrosion resistance in Hydrogen Sulfide. Subject to damaging carbide precipitation in the 900°F to 1600°F range. (482°C to 871°C)

Sheath Diameters

0.010"

0.020"

0.032"

0.040"

0.063"

0.313"

0.125"

0.375"

0.188"

0.500"

0.250"

| Type | 0.040" | 0.063" | 0.125" | 0.188" | 0.250" | 0.375" |

|---|---|---|---|---|---|---|

| J | 900 °F | 1000 °F | 1000 °F | 1200 °F | 1200 °F | 1200 °F |

| K | 1400 °F | 1800 °F | 1800 °F | 2000 °F | 2000 °F | 2000 °F |

| T | 300 °F | 400 °F | 400 °F | 700 °F | 700 °F | 700 °F |

| E | 800 °F | 1000 °F | 1000 °F | 1000 °F | 1100 °F | 1200 °F |

Thermocouple Grade Wire

| Calibration Type |

Temperature Range | Tolerance Whichever is GREATER | ||||

|---|---|---|---|---|---|---|

| J | 32 to 1382°F | 0 to 750°C | ? 2.2°C or ? 0.75% | ? 1.1°C or ? 0.4% | ||

| K | 32 to 2282°F | 0 to 1250°C | ? 2.2°C or ? 0.75% | ? 1.1°C or ? 0.4% | ||

| E | 32 to 1652°F | 0 to 900°C | ? 1.7°C or ? 0.5% | ? 1.0°C or ? o.4% | ||

| T | 32 to 662°F | 0 to 350°C | ? 1.0°C or ? 0.75% | ? 0.5°C or ? 0.4% | ||

| R or S | 32 to 2642°F | 0 to 1450°C | ? 1.5° or ? 0.25% | ? 0.6°C or ? 0.4% | ||

| B | 1598 to 3092°F |

870 to 1700°C | ? 0.5% | |||

| N | 32 to 2282°F | 0 to 1250°C |

? 2.2°C or ? 0.75% | ? 1.1°C or ? 0.4% | ||

Thermocouple Extension Grade Wire

| Calibration Type |

Temperature Range | Tolerance Whichever is GREATER | ||

|---|---|---|---|---|

| JX | 32 to 392°F | 0 to 200°C | ? 2.2°C | ? 1.1°C |

| KX | 32 to 392°F | 0 to 200°C | ? 2.2°C | ? 1.1°C |

| EX | 32 to 392°F | 0 to 200°C | ? 1.7°C | ? 1.0°C |

| TX | 32 to 212°F | 0 to 200°C | ? 1.0°C | ? 0.5°C |

| NX | 32 to 392°F | 0 to 200°C | ? 2.2° | ? 1.1°C |

Junctions

G=Grounded

Has the fastest response time ideal for measuring rapid temperature changes. Clear coating on most models provides a humidity barrier for the thermocouple. Do not use with corrosive fluids or atmospheres. See table at right for recommended atmosphere type for exposed-junction probes.

U=Ungrounded

Has a welded junction insulated from the protective sheath and is electrically isolated. Longer response time; use for conductive solutions or where isolation of the measuring circuitry is required.

E=Exposed

Has a junction welded to tip of sheath. Wires are completely sealed from contaminants. Good response time

Immersion Length/ Sheath Length

Length of sheath is measure from the sensing junction to the beginning of the first fixed obstruction, termination or transition.

Leadwire

L1=Wire Exposed

Lead Length

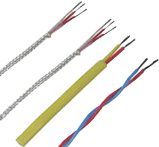

Protective Coverings

Terminations

P = Male Plug *(MP= Mini Plug)

Fixed Fitting

| FXS | NPT | |

|---|---|---|

| 1 | = | 1/8" |

| 2 | = | 1/4" |

| 3 | = | 3/8" |

| 4 | = | 1/2" |

| 5 | = | 3/4" |

| 6 | = | 1" |

| FXD | Head/Process | |

|---|---|---|

| = | 1/8" x 1/8" | |

| 2 | = | 1/4" x 1/4" |

| 3 | = | 1/2" x 3/8" |

| 4 | = | 1/2" x 1/2" |

| 5 | = | 3/4" x 3/4" |

Adjustable Fittings

| N.P.T | I.D. | S.S | BRASS | C.S. | ||||

|---|---|---|---|---|---|---|---|---|

| 1/8" | = | 1/16" | = | SSF2 | = | BF2 | = | SF2 |

| 1/8" | = | 1/8" | = | SSF4 | = | BF4 | = | SF4 |

| 1/8" | = | 3/16" | = | SSF7 | = | BF7 | = | SF7 |

| 1/4" | = | 3/16" | = | SSF8 | = | BF8 | = | SF8 |

| 1/8" | = | 1/4" | = | SSF9 | = | BF9 | = | SF9 |

| 1/4" | = | 1/4" | = | SSF10 | = | BF10 | = | SF10 |

| 1/2" | = | 1/4" | = | SSF11 | = | BF11 | = | SF11 |

- O's hit Bautista twice, Showalter tossed

- Phils clinch playoff spot despite loss

- Reds trim magic number to 1, rout Padres

- Cain flirts with no-hitter, Giants win

- Phils clinch playoff spot despite loss

- Reds trim magic number to 1, rout Padres

- Mariners halt Rays' winning streak at 4

- Sloppy Braves fall to Nationals 4-2

- Yanks end skid, rally past Red Sox in 10

- Lee to start playoff opener for Rangers

FIND US ON FACEBOOK

Thermowell Design Factors

Thermowells are pressure-tight receptacles that extend the life of a temperature in environments where the sensor is not chemically compatible with the process media or the sensor does not have the mechanical strength to withstand the process flow or pressure. Thermowells also facilitate removing, changing, checking or replacing sensors without draining the process system. The use of standardized thermowells throughout a plant permits easy relocation of sensors.

About Temperature

In a qualitative manner, we can describe the temperature of an object as that which determines the sensation of warmth or coldness felt from contact with it. It is easy to demonstrate that when two objects of the same material are placed together (physicists say when they are put in thermal contact), the object with the higher temperature cools while the cooler object becomes warmer until a point is reached after which no more change occurs, and to our senses, they feel the same.

Introduction to Thermowells

In general, the thermowell material to be chosen for an installation is governed mainly by the corrosion conditions the well will face. The high polish given to all stainless and Monel wells provides maximum corrosion resistance. Occasionally, the primary consideration is one of strength rather than corrosion resistance.

Selection the Right Thermowell

In many pressurised processes it is often not possible or advisable to insert the temperature instrument directly into the media being measured. A thermowell protects the temperature instrument, permits the instrument to be exchanged or calibrated, and keeps dangerous or expensive media within the process installation.

Selecting Wire Insulation

To select wire the instrumentation engineer specifies the conductor to be used, ie copper, or silver wire, or a type of thermocouple wire. The next consideration is the insulation. (Insulation is sometimes referred to as "dielectric"). The types include Teflon, PVC, polyethylene, rubber, etc.

Types of Sheath Material

When selecting a element sheath material consideration should be given to compatibility with the heated medium. Standard element sheaths available are steel, stainless steel, copper and incoloy.

Thermistor

A thermistor is a type of resistor whose resistance varies significantly (more than in standard resistors) with temperature. The word is a pormantaeu of thermal and resistor. Thermistors are widely used as inrush current limiters, temperature , self-resetting overcurrent protectors, and self-regulating heating elements.

Tubeskin Sensor Design

Thermometrics Corporation manufactures temperature sensors, radiant tubeskin thermocouples, petrochemical sensors and gasifer thermocouples for refining facilities around the world. Tube skin refinery thermocouples manufactured with superior metallurgy are used to measure the temperature of process such as Coker, Purge Gas Recovery, Primary Reformer, and Synthesis Converter systems.