ANSI B 16.5 Class 150 Flange

We offer high quality threaded flanges that are dimensionally accurate and highly resistant to corrosion. These flanges ANSI B 16.5 Class 150, high pressure flanges can be easily assembled into any pipe without welding. Threaded Pipe Flanges, Flange ANSI B 16.5 Class 150, Class 150 ANSI B 16.5 can be used in extremely high pressure services, particularly at or near atmospheric temperature. We offer these Threaded Pipe Flanges, Flange ANSI B 16.5 Class 150 in proper packaging to avoid any damage during the transportation.

We offer a wide range of ANSI B 150 Class- Threaded Flanges that comply with relevant industry standards. Our range of flanges are widely appreciated for their dimensional accuracy and corrosion and rust resistant properties. These flanges require less maintenance and are ideal for high temperature and pressure applications.

Notes

•The thread conforms to ASME B1. 20.1 NTP threads.(The only exceptions are small male and female plain face threaded flanges which use NPSL locknut threads)

•Class 300 and higher threaded flanges are counter-bored. Threads are chamfered to the counterbore at an angle of 450 (approx)

•Weights are based on manufacturer's data and are approximate

ANSI B 16.5 Class 300 lb Flange

We are a prominent manufacturer and exporter of best quality threaded flanges, which are in demand in global marketplace. Precision engineered, these Threaded Steel Flanges and ANSI B 16.5 Class 300 lb can be easily fitted into pipe without welding. Optimization of high grade materials imparts to them utmost level of durability. We offer these Threaded Steel Flanges and ANSI B 16.5 Class 300 lb in bulk quantities and at industry leading prices.

Our wide assortment of ANSI B 16.5 Class 300 - Threaded Flanges are manufactured using finest grade of metal alloys. The dimensions of these flanges correspond to the inside diameter of the pipe and has a standard wall thickness. We offer these flanges in the different dimensions and weight as per the clients' requirements.

Notes

•The thread conforms to ASME B1. 20.1 NTP threads.(The only exceptions are small male and female plain face threaded flanges which use NPSL locknut threads)

•Class 300 and higher threaded flanges are counter-bored. Threads are chamfered to the counterbore at an angle of 450 (approx)

•Weights are based on manufacturer's data and are approximate

ANSI B 16.5 Class 600 lb

We are a well-reckoned name involved in manufacturing, supply and export of high grade ANSI Flanges, threaded ANSI flanges, ANSI B 16.5 class 600 lb. Complying with international quality standards, these threaded flanges find application in diverse industries including railway, cement, port, mining etc. Flawlessly designed, these ANSI flanges, threaded ANSI flanges, ANSI B 16.5 class 600 lb are easy to install and available at competitive pricing.

We are a leading manufacturer of ANSI B 16.5 Class 600 - Threaded Flanges that are manufactured using high grade steel. These flanges find application in low pressure services at ambient temperature. Manufactured using advanced technology, our range has been widely appreciated for dimensional accuracy, resistance to corrosion and rust.

Notes

•The thread conforms to ASME B1. 20.1 NTP threads.(The only exceptions are small male and female plain face threaded flanges which use NPSL locknut threads)

•Class 300 and higher threaded flanges are counter-bored. Threads are chamfered to the counterbore at an angle of 450 (approx)

•Weights are based on manufacturer's data and are approximate

ANSI B 16.5 Class 900 lb Flange

Catering to the needs of diverse industries, we manufacture and export a comprehensive range of weld neck flanges. These flanges are fabricated by us using high grade materials, procured from the reputed vendors of the markets. Our range of flanges is used to weld the joint to provide extra strength. They can be used in high-pressure as well as extreme temperature applications.

Our range of ANSI B 16.5 Class 900 lb Weld-neck flanges easily fit inside the pipe and provide a sturdy grip. These flanges find application in diverse industries like construction, automation, petro-chemicals etc. Highest grade of material make our flanges durable, resistant to corrosion and extreme temperature.

Notes

•The thread conforms to ASME B1. 20.1 NTP threads.(The only exceptions are small male and female plain face threaded flanges which use NPSL locknut threads)

•Class 300 and higher threaded flanges are counter-bored. Threads are chamfered to the counterbore at an angle of 450 (approx)

•Weights are based on manufacturer's data and are approximate

ANSI B 16.5 Class 1500 lb Flange

We are an internationally recognized manufacturer and supplier of top quality steel socket flanges, steel socket welding flanges, that are widely acclaimed in different industries. For fabricating these flanges, we use premium quality materials, which makes them corrosion resistant and highly durable. Conforming to industrial norms, these flanges are available in various sizes and dimensions.

Notes

•Class 400 socket weld flanges may be provided in NPS ? TO 2 ? using Class 600 dimensions

•Dimensions B corresponds to the pipe inside diameter. Values quoted assume 40S/ Standard wall thickness

•Weights are based on manufacturer's data and are approximate.

ANSI B 16.5 Class 2500 lb Flange

We are a well-established manufacturer and exporter of premium standard ANSI blind flanges, standard blind flanges, blind stainless flanges, blind steel flanges, which are also known as blanking flanges and used in different industries such as paper, chemical, cement, oil & gas etc. These dimensionally accurate ANSI blind flanges, standard blind flanges, blind stainless flanges are used to close the ends of pipes, valves, pressure vessel openings. Our ANSI blind flanges, standard blind flanges, blind stainless flanges, blind steel flanges are at par with international quality standards.

Notes

•Weights are based on manufacturer's data and are approximate.

TYPE R THERMOCOUPLE (Platinum / Rhodium)

Composed of a positive leg which is approximately 70% Platinum, 30% Rhodium and a negative leg which is approximately 94% Platinum, 6% Rhodium.

When protected by compacted mineral insulation and appropriate outer sheath, Type R is usable from 0 to 1482°C, ( 32 to 2700°F).Type R has a higher EMF output than type S. Also easily contaminated, and damaged by reducing atmospheres. Type R should by protected in a similar fashion as Type S.

Thermocouple Order Code

Sheath Material

304 = 304 S.S. Most commonly used low temperature sheath material. Good corrosion resistance. Subject to damaging carbide precipitation in the 900°F to 1600°F range. (482°C to 871°C)

316 = 316 S.S. Best corrosion resistance of the austenetic stainless steel grades. Good corrosion resistance in Hydrogen Sulfide. Subject to damaging carbide precipitation in the 900°F to 1600°F range. (482°C to 871°C)

310 = 310 S.S. Mechanical and corrosion resistance similar to but better than 304 S.S. Very good heat resistance. This alloy contains 25% Cr, 20% Ni. Not as ductile as 304 S.S.

INC = Inconel 600 Best corrosion resistance of the austenetic stainless steel grades. Good corrosion resistance in Hydrogen Sulfide. Subject to damaging carbide precipitation in the 900°F to 1600°F range. (482°C to 871°C)

Sheath Diameters

0.010"

0.020"

0.032"

0.040"

0.063"

0.313"

0.125"

0.375"

0.188"

0.500"

0.250"

Recommended upper temperature limits for sheath type thermocouples

| Type |

0.040" |

0.063" |

0.125" |

0.188" |

0.250" |

0.375" |

| J |

900 °F |

1000 °F |

1000 °F |

1200 °F |

1200 °F |

1200 °F |

| K |

1400 °F |

1800 °F |

1800 °F |

2000 °F |

2000 °F |

2000 °F |

| T |

300 °F |

400 °F |

400 °F |

700 °F |

700 °F |

700 °F |

| E |

800 °F |

1000 °F |

1000 °F |

1000 °F |

1100 °F |

1200 °F |

NOTE: The recommended temperatures shown are suggested maximum temperatures at which a thermocouple should yield satisfactory life. Due to the variables of each application, in certain instances the upper limit shown maybe exceeded without decreasing thermocouple life. Conversely, other applications may decrease service life if used at recommended upper limits. Consult our factory for suggested maximum temperatures for your requirements.

Thermocouple Grade Wire

Calibration

Type |

Temperature Range |

Tolerance Whichever is GREATER |

| J |

32 to 1382°F |

0 to 750°C |

? 2.2°C or ? 0.75% |

? 1.1°C or ? 0.4% |

| K |

32 to 2282°F |

0 to 1250°C |

? 2.2°C or ? 0.75% |

? 1.1°C or ? 0.4% |

| E |

32 to 1652°F |

0 to 900°C |

? 1.7°C or ? 0.5% |

? 1.0°C or ? o.4% |

| T |

32 to 662°F |

0 to 350°C |

? 1.0°C or ? 0.75% |

? 0.5°C or ? 0.4% |

| R or S |

32 to 2642°F |

0 to 1450°C |

? 1.5° or ? 0.25% |

? 0.6°C or ? 0.4% |

| B |

1598 to 3092°F

|

870 to 1700°C |

? 0.5% |

|

| N |

32 to 2282°F |

0 to 1250°C

|

? 2.2°C or ? 0.75% |

? 1.1°C or ? 0.4% |

Thermocouple Extension Grade Wire

Calibration

Type |

Temperature Range |

Tolerance Whichever is GREATER |

| JX |

32 to 392°F |

0 to 200°C |

? 2.2°C |

? 1.1°C |

| KX |

32 to 392°F |

0 to 200°C |

? 2.2°C |

? 1.1°C |

| EX |

32 to 392°F |

0 to 200°C |

? 1.7°C |

? 1.0°C |

| TX |

32 to 212°F |

0 to 200°C |

? 1.0°C |

? 0.5°C |

| NX |

32 to 392°F |

0 to 200°C |

? 2.2° |

? 1.1°C |

Junctions

G=Grounded

Has the fastest response time ideal for measuring rapid temperature changes. Clear coating on most models provides a humidity barrier for the thermocouple. Do not use with corrosive fluids or atmospheres. See table at right for recommended atmosphere type for exposed-junction probes.

U=Ungrounded

Has a welded junction insulated from the protective sheath and is electrically isolated. Longer response time; use for conductive solutions or where isolation of the measuring circuitry is required.

E=Exposed

Has a junction welded to tip of sheath. Wires are completely sealed from contaminants. Good response time

Immersion Length/ Sheath Length

Length of sheath is measure from the sensing junction to the beginning of the first fixed obstruction, termination or transition.

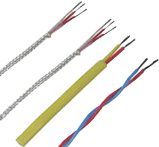

Leadwire

L1=Wire Exposed

L2= PVC Insulated Lead Wire (Rated 105°C, Epoxy Potted)

L3= Teflon Insulated Lead Wire (Rated 204°C, Epoxy Potted

L4= Fiberglass Insulated Lead Wire (Rated 204°C, Expoxy Potted)

L5= Fiberglass Insulated Lead Wire (Rated 510°C, Ceramic Cement Potted

CC= Coil Cord

Lead Length

Protective Coverings

SS = Stainless Steel Overbraid

TCTU = Tinned Copper Overbraid

FA* = Stainless Steel Flex Armor

TFA* = Teflon Coated Stainless Steel Flex Armor

PFA* = PVC Coated Stainless Steel Flex Armor

* Add Length to Armor Code. (Example: PFA24)

Terminations

P = Male Plug *(MP= Mini Plug)

J = Female Jack * (MJ= Mini Jack)

ASCH = Aluminum Screw Cover Head

PH = Plastic Screw Cover Head

MPH = Mini Plastic Screw Cover Head

MAH = Mini Aluminum Screw COver Head

EXH = Explosion Proof Head (USL,CSA)

HCH = Hinged Cover Head

HPH = High Profile Hinged Screw Cover Head

SL = Spade Lugs (#10 Screw Size)

BW = Bare Wire

Fixed Fitting

| FXS |

|

NPT |

| 1 |

= |

1/8" |

| 2 |

= |

1/4" |

| 3 |

= |

3/8" |

| 4 |

= |

1/2" |

| 5 |

= |

3/4" |

| 6 |

= |

1" |

| FXD |

|

Head/Process |

|

= |

1/8" x 1/8" |

| 2 |

= |

1/4" x 1/4" |

| 3 |

= |

1/2" x 3/8" |

| 4 |

= |

1/2" x 1/2" |

| 5 |

= |

3/4" x 3/4" |

Adjustable Fittings

| N.P.T |

|

I.D. |

|

S.S |

|

BRASS |

|

C.S. |

| 1/8" |

= |

1/16" |

= |

SSF2 |

= |

BF2 |

= |

SF2 |

| 1/8" |

= |

1/8" |

= |

SSF4 |

= |

BF4 |

= |

SF4 |

| 1/8" |

= |

3/16" |

= |

SSF7 |

= |

BF7 |

= |

SF7 |

| 1/4" |

= |

3/16" |

= |

SSF8 |

= |

BF8 |

= |

SF8 |

| 1/8" |

= |

1/4" |

= |

SSF9 |

= |

BF9 |

= |

SF9 |

| 1/4" |

= |

1/4" |

= |

SSF10 |

= |

BF10 |

= |

SF10 |

| 1/2" |

= |

1/4" |

= |

SSF11 |

= |

BF11 |

= |

SF11 |